The architectural landscape is experiencing a remarkable transformation, with door panels emerging as pivotal design elements that define both aesthetic appeal and functional performance in contemporary spaces. Modern door panels represent far more than simple barriers between rooms; they serve as artistic statements that reflect evolving design philosophies and technological advancements in building materials. From residential homes to commercial establishments, the selection of appropriate door panels significantly impacts the overall ambiance and spatial flow of any environment.

Today's market offers an unprecedented variety of materials, textures, and finishing techniques that cater to diverse architectural styles and personal preferences. The integration of advanced manufacturing processes has enabled designers and architects to push creative boundaries while maintaining structural integrity and durability. This evolution reflects a broader trend toward customization and personalization in interior design, where every element contributes to creating unique and memorable spaces.

Contemporary Design Trends in Panel Architecture

Minimalist Aesthetics and Clean Lines

The minimalist movement has profoundly influenced modern door panel design, emphasizing simplicity, functionality, and visual clarity. Contemporary designers favor clean geometric forms that eliminate unnecessary ornamentation while maximizing visual impact through proportion and material quality. This approach creates panels that serve as subtle yet sophisticated design elements, complementing rather than competing with surrounding architectural features.

Flat-panel designs have gained tremendous popularity in residential and commercial applications, offering versatility that adapts to various interior styles. These streamlined surfaces provide excellent canvases for exploring different materials and finishes, from natural wood grains to innovative synthetic composites. The emphasis on horizontal and vertical lines creates visual continuity that enhances spatial perception and flow.

Integration of Natural Materials

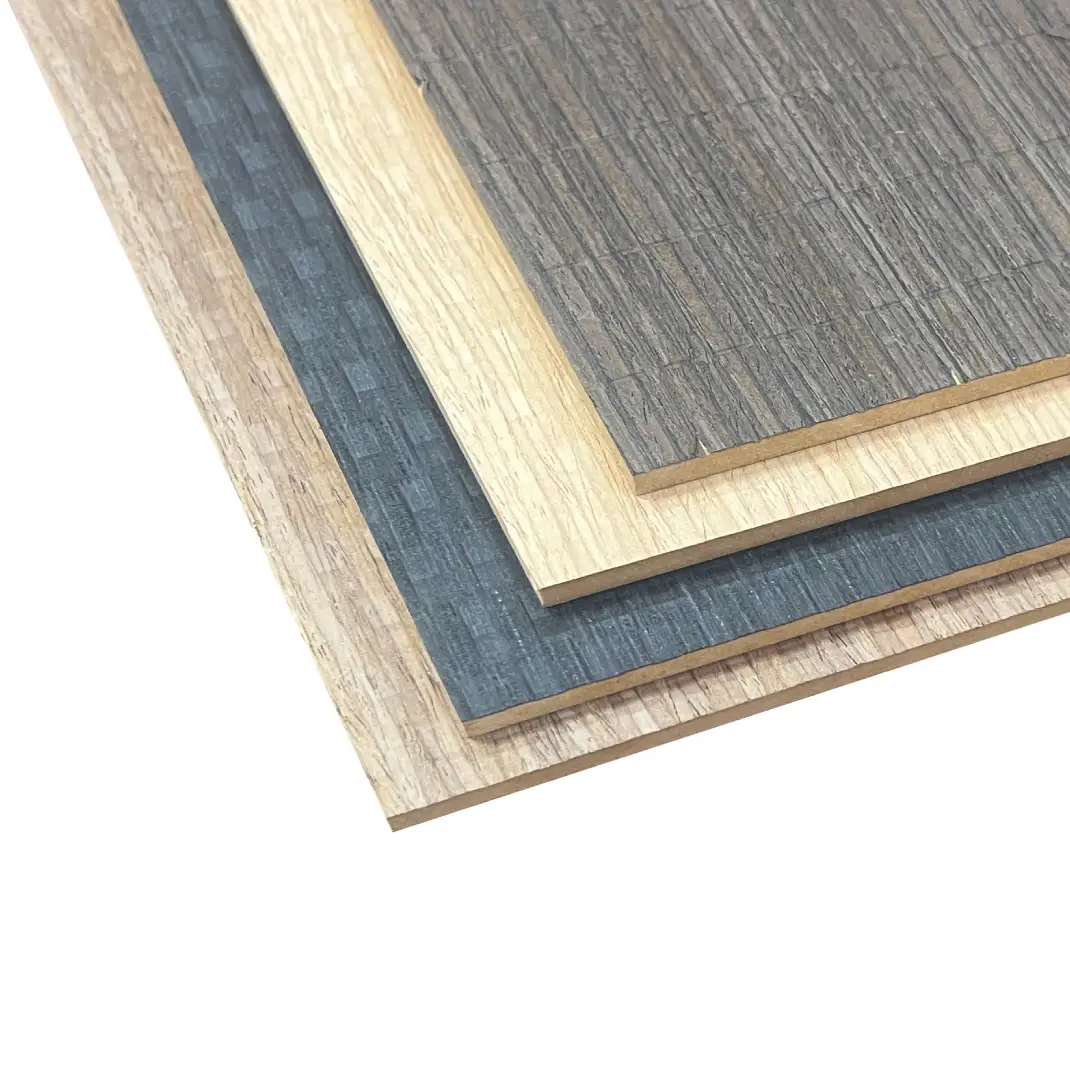

Environmental consciousness and biophilic design principles have driven renewed interest in natural materials for door panel construction. Wood species selection has expanded beyond traditional options to include sustainably harvested exotic varieties that offer unique grain patterns and color variations. These natural elements bring warmth and authenticity to modern spaces while supporting eco-friendly building practices.

Bamboo, reclaimed timber, and certified sustainable hardwoods represent growing segments in the panel market. These materials not only provide environmental benefits but also offer distinctive aesthetic qualities that synthetic alternatives cannot replicate. The natural variation and aging characteristics of organic materials create panels that develop character over time, adding depth and personality to interior environments.

Innovative Manufacturing Technologies

Advanced Surface Texturing Techniques

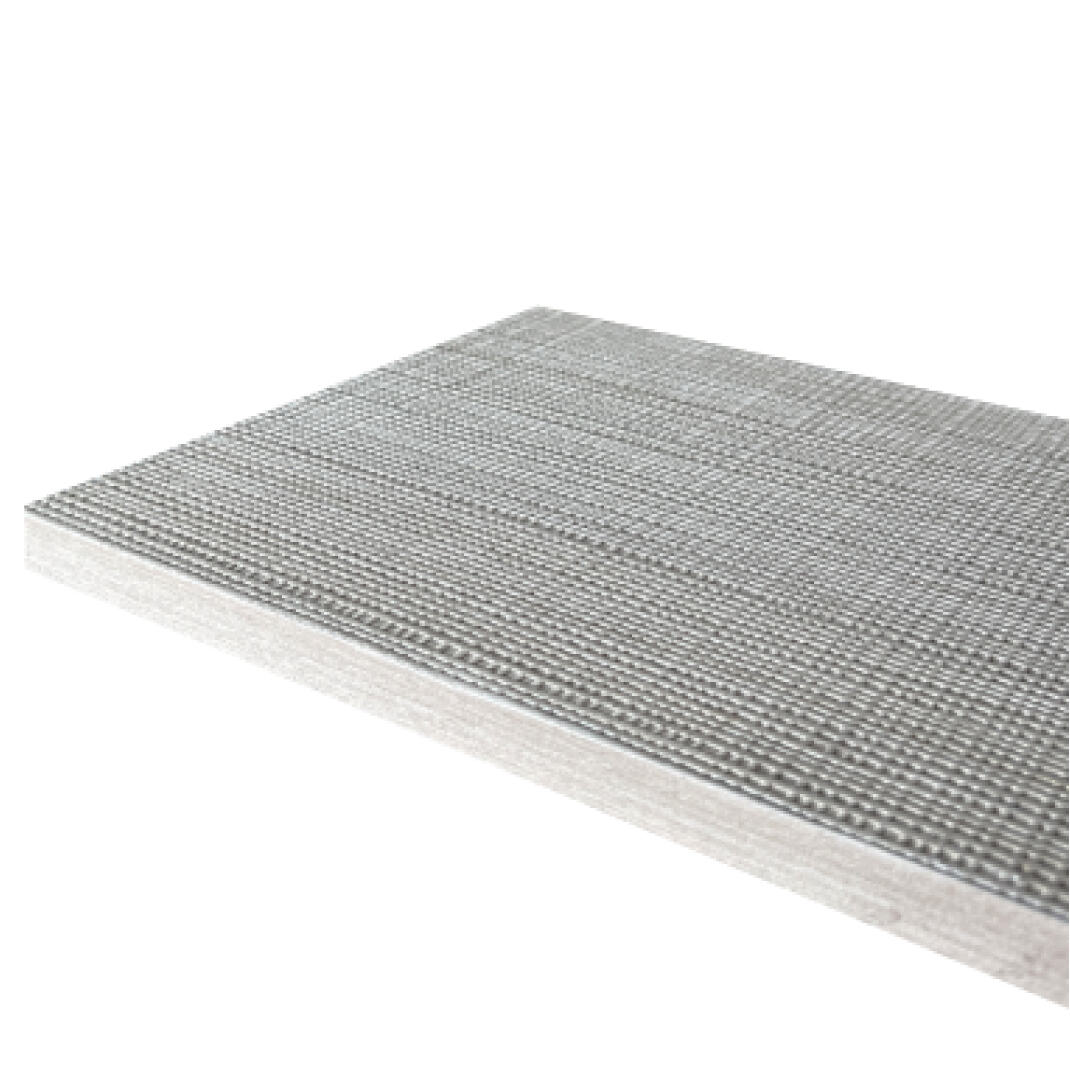

Modern manufacturing capabilities have revolutionized surface treatment options for door panels, enabling the creation of intricate textures and patterns that were previously impossible to achieve. Embossing technologies can replicate natural materials with remarkable accuracy, providing cost-effective alternatives that maintain visual authenticity. These processes allow manufacturers to create consistent patterns across large production runs while offering customization options for specific projects.

Digital printing and laser etching techniques have opened new possibilities for incorporating graphic elements, logos, and custom designs directly into panel surfaces. These technologies enable architects and designers to create truly unique installations that reflect brand identity or artistic vision. The precision and repeatability of digital processes ensure consistent quality while reducing production time and costs.

Composite Material Innovation

The development of advanced composite materials has expanded design possibilities while addressing practical concerns such as moisture resistance, dimensional stability, and maintenance requirements. High-density fiberboard (HDF) and medium-density fiberboard (MDF) substrates provide excellent foundations for various surface treatments while maintaining structural integrity under challenging conditions.

Engineered wood products combine the aesthetic appeal of natural materials with enhanced performance characteristics. These composites resist warping, splitting, and moisture damage while providing consistent dimensional stability throughout their service life. Advanced adhesive systems and pressing techniques create panels that exceed the performance of traditional solid wood construction in many applications.

Functional Performance Enhancements

Acoustic Properties and Sound Control

Modern door panels increasingly serve dual purposes as architectural elements and acoustic control devices. Specialized core materials and construction techniques can significantly reduce sound transmission between spaces while maintaining aesthetic appeal. Honeycomb cores, mineral wool insulation, and laminated constructions provide excellent sound-dampening properties without compromising visual design.

The growing emphasis on open-plan living and working environments has created demand for panels that define spaces without completely isolating them. Acoustic door panels strike this balance by providing privacy and noise control while maintaining visual connectivity and natural light flow. These solutions prove particularly valuable in residential lofts, modern offices, and hospitality environments.

Fire Resistance and Safety Features

Building code requirements and safety considerations have driven innovations in fire-resistant panel construction. Modern fire-rated door panels incorporate specialized core materials and surface treatments that provide extended fire resistance while maintaining design flexibility. These products enable architects to meet stringent safety requirements without compromising aesthetic vision or functional performance.

Intumescent coatings and fire-resistant core materials work together to provide passive fire protection that activates only when needed. These systems remain virtually invisible during normal use but provide critical protection in emergency situations. The integration of safety features into standard panel construction has made fire-rated options more accessible and cost-effective for various applications.

Customization and Personalization Options

Digital Design Integration

Computer-aided design tools and digital visualization technologies have transformed the customization process for door panels, enabling clients to preview and modify designs before production begins. Three-dimensional rendering capabilities provide realistic representations of proposed installations, facilitating informed decision-making and reducing costly modifications during construction phases.

Parametric design software allows for rapid exploration of different configurations, materials, and finishes while maintaining design intent and structural requirements. This technology enables architects and designers to optimize panel specifications for specific applications while ensuring compatibility with existing architectural elements. The ability to visualize complex installations reduces communication barriers and ensures project stakeholders share common expectations.

Modular System Approaches

Modular panel systems provide flexibility for future modifications and expansions while simplifying initial installation processes. Standardized connection methods and component dimensions enable rapid assembly and disassembly when space requirements change. These systems prove particularly valuable in commercial environments where layout modifications occur frequently.

Interchangeable components within modular systems allow for easy maintenance and updating without replacing entire installations. Individual panels can be removed, refinished, or replaced as needed while maintaining system integrity and aesthetic continuity. This approach reduces long-term maintenance costs while providing opportunities for refreshing interior appearances without major renovation projects.

Installation and Maintenance Considerations

Professional Installation Requirements

Proper installation techniques significantly impact the long-term performance and appearance of modern door panels, requiring skilled professionals who understand specific product requirements and industry best practices. Precision measurement, appropriate fastening methods, and proper sealing ensure optimal functionality while preventing common problems such as warping, binding, or premature wear.

Modern panel systems often incorporate sophisticated hardware and adjustment mechanisms that require specialized knowledge and tools for proper installation. Professional installers understand manufacturer specifications and can identify potential issues before they become costly problems. Investment in quality installation services protects the initial investment while ensuring warranty coverage remains valid.

Long-Term Care and Maintenance

Contemporary door panels benefit from regular maintenance programs that preserve appearance and extend service life while minimizing repair costs. Different materials require specific care approaches, from periodic oiling of natural wood surfaces to gentle cleaning of synthetic finishes. Understanding maintenance requirements during the selection process helps ensure long-term satisfaction with chosen products.

Preventive maintenance schedules can identify minor issues before they develop into major problems requiring panel replacement. Regular inspection of hardware, seals, and surface conditions enables prompt attention to wear patterns or damage that could compromise functionality or appearance. Professional maintenance services provide expertise and specialized products that may not be available to individual property owners.

FAQ

What are the most durable materials for modern door panels

The most durable materials for modern door panels include engineered wood composites, high-pressure laminates, and metal-core constructions with protective surface finishes. These materials resist moisture, temperature variations, and mechanical stress while maintaining dimensional stability over extended periods. Proper material selection depends on specific application requirements, environmental conditions, and expected usage patterns.

How do acoustic door panels differ from standard designs

Acoustic door panels incorporate specialized core materials such as mineral wool or foam insulation along with mass-loaded vinyl barriers to reduce sound transmission. These panels typically feature thicker construction and sealed edges to prevent sound leakage around perimeters. Surface materials may also include perforated patterns or fabric coverings that enhance sound absorption characteristics.

What maintenance is required for textured panel surfaces

Textured panel surfaces require gentle cleaning methods that avoid damage to surface patterns or protective finishes. Soft brushes or microfiber cloths work well for removing dust and debris from textured areas, while mild cleaning solutions can address more stubborn stains. Avoid harsh chemicals, abrasive cleaners, or high-pressure washing that could damage delicate surface textures or protective coatings.

Can existing door panels be upgraded with modern features

Existing door panels can often be upgraded through refinishing, hardware replacement, or the addition of decorative elements such as applied moldings or surface treatments. However, structural modifications such as adding fire resistance or acoustic properties typically require complete panel replacement. Professional evaluation can determine which upgrade options are feasible for specific installations while maintaining safety and performance standards.