LMQ5009

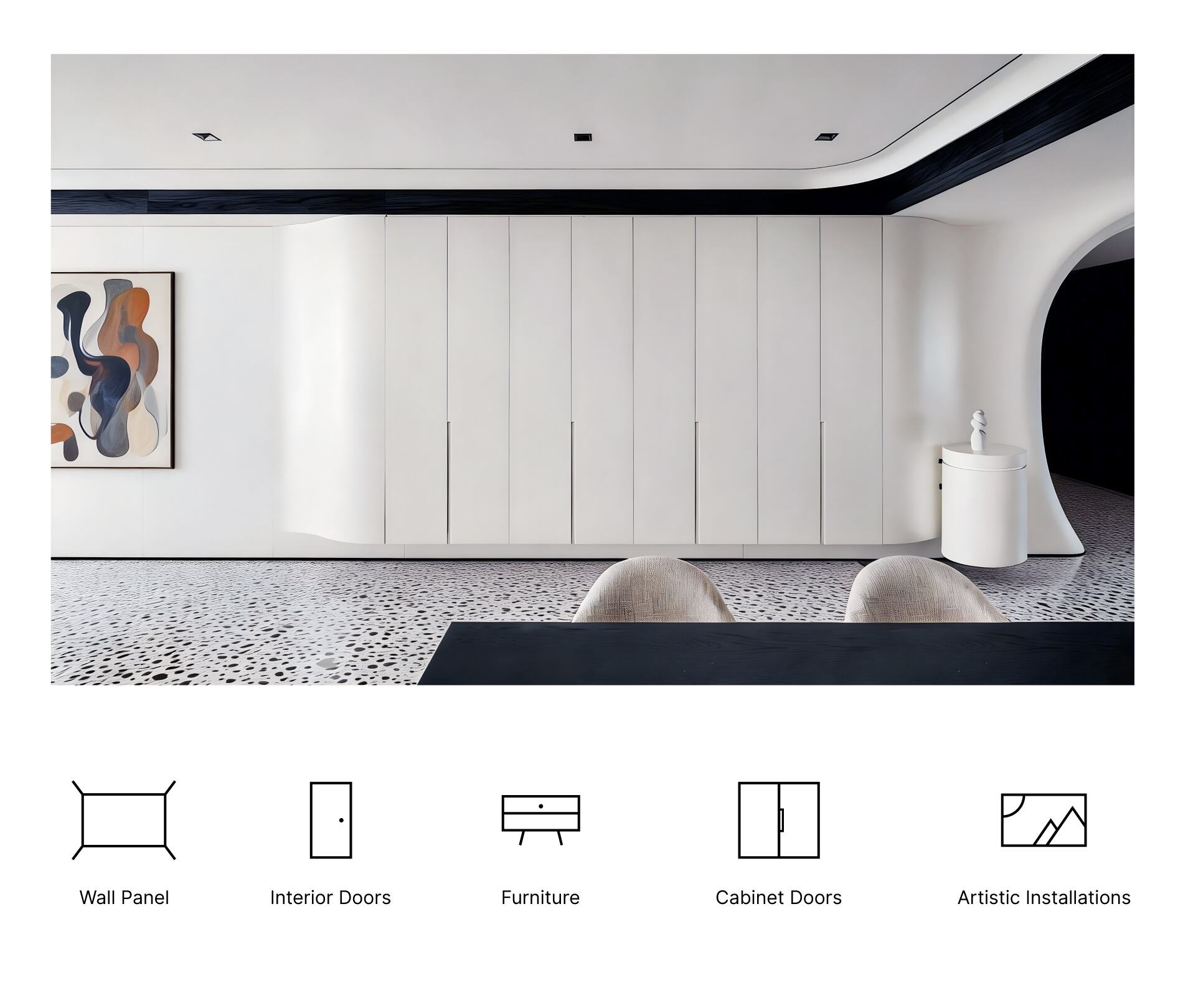

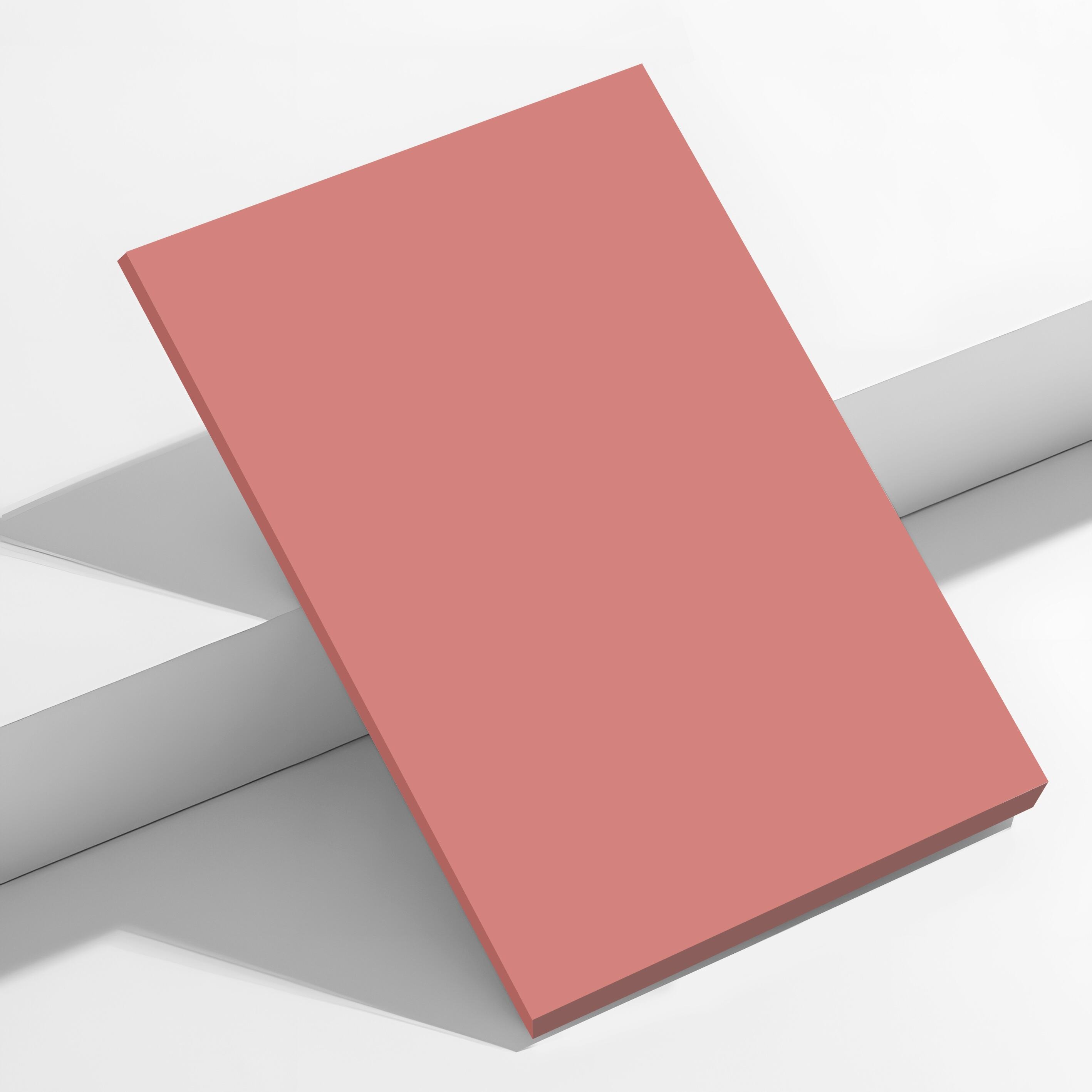

Lamarty 4H Excimer Skin-Feel Panels feature 12 ultra-matte colors. Widely used in residential, office, and commercial spaces, they offer a versatile, premium, and sophisticated minimalist aesthetic.

- Overview

- Description

- Instruction

- Specification

- Advantage

- Application

- Recommended Products

| Place of Origin: | China |

| Brand Name: | Lamarty |

| Model Number: | LMQ5009 |

| Certification: | FSC、Carbp2 |

We utilize professional coating processes from Sherwin-Williams. The first coat features a high-performance adhesion primer specifically designed for melamine boards, providing exceptional grip to eliminate delamination while preserving original colors and enhancing processability.

The second coat applies a non-yellowing, low-odor sanding primer through forward and reverse roller coating, ensuring a mirror-smooth surface that is both color-stable and environmentally friendly.

| Size | 1200 x 2440/3050mm |

| Thickness | 18mm |

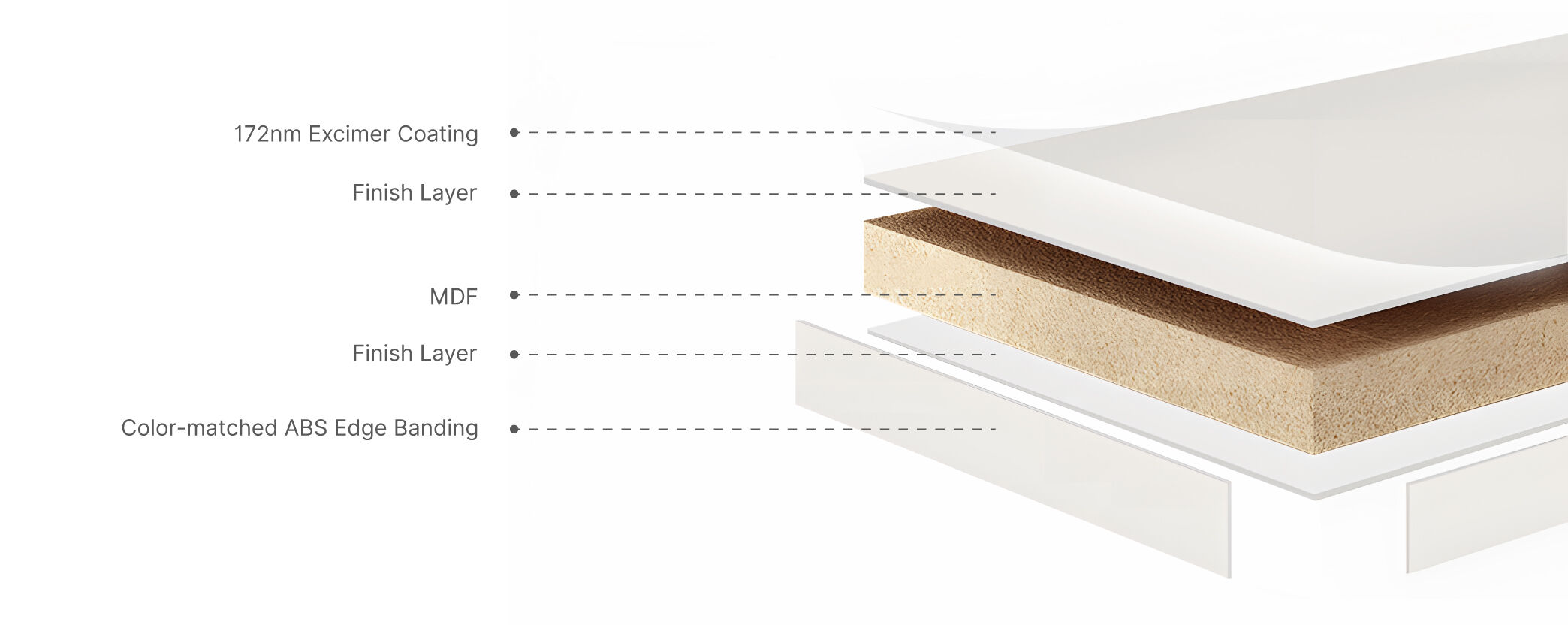

| Substrate | MDF |

| Process | 172nm Excimer UV Curing(Single-sided / Double-sided) |

| Environmental Grade | CARB P2 |

| Edge Banding | Color-matched ABS |

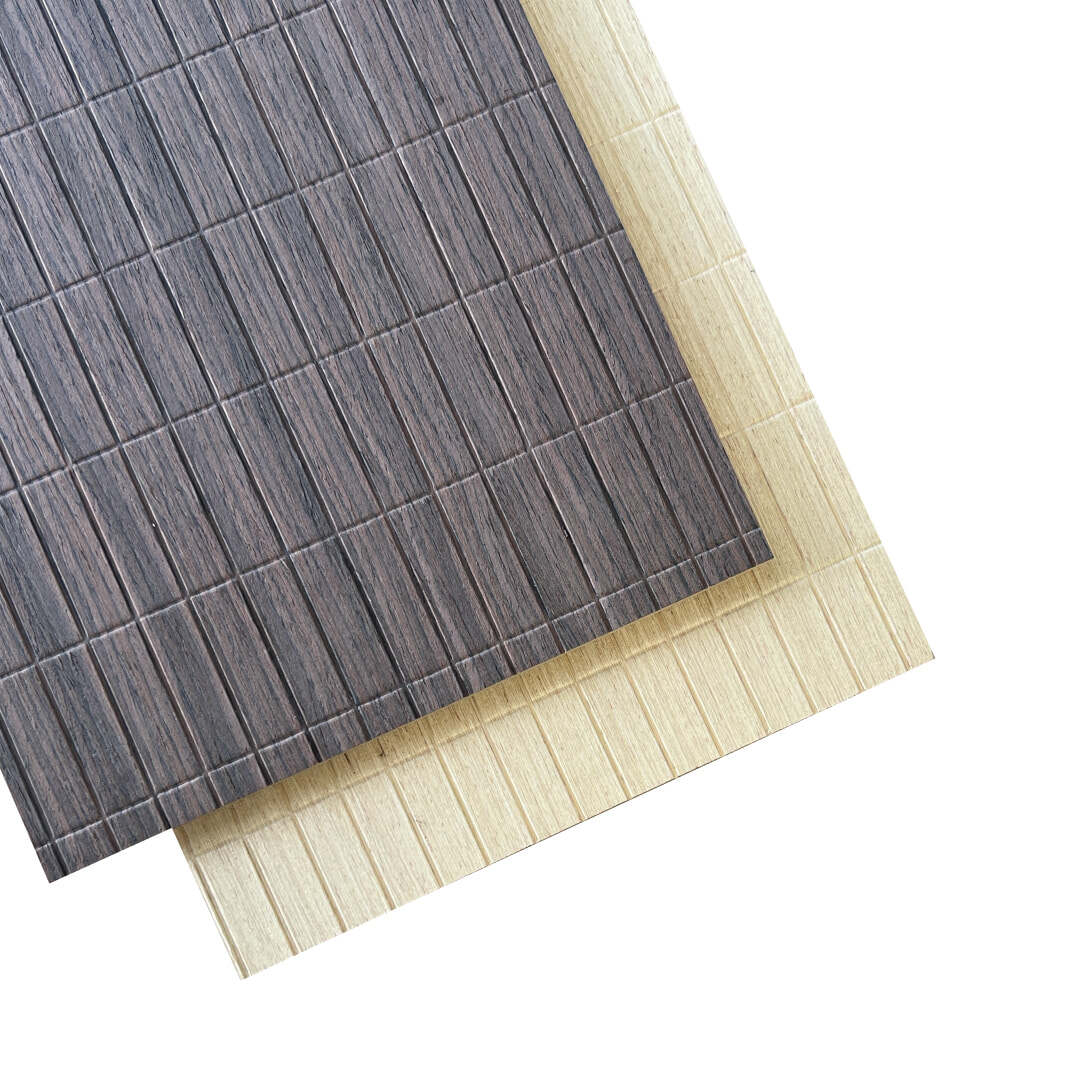

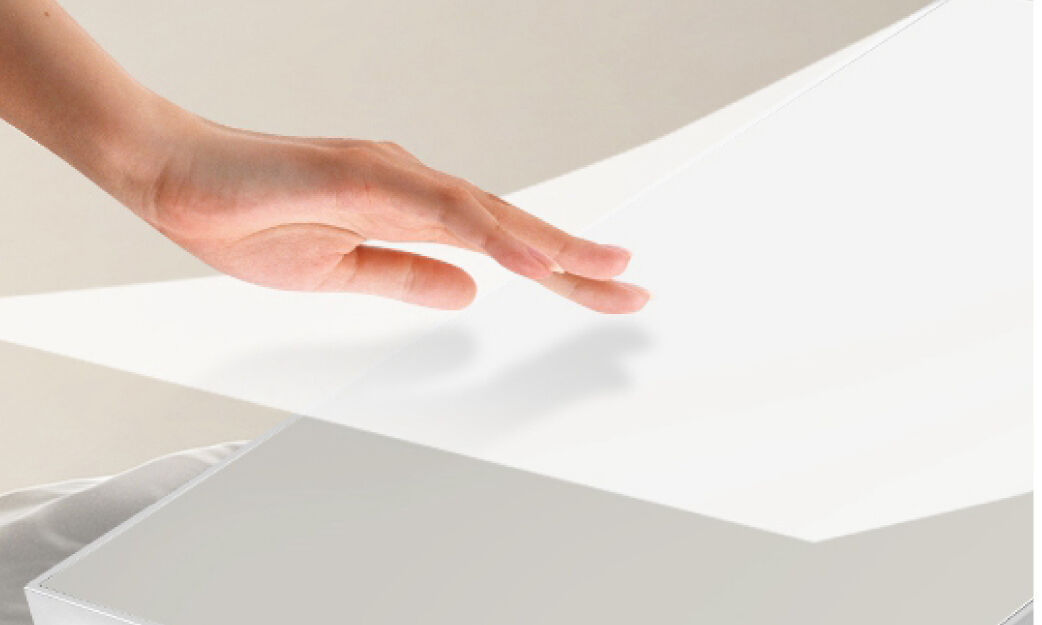

Utilizing a 172nm wavelength excimer UV light source within an inert gas environment, this high-precision coating process achieves a superior matte finish with a soft-touch feel. The high-energy chemical reaction triggered in a pure nitrogen atmosphere significantly increases surface hardness and density, effectively eliminating issues like fingerprints and scratches.

|

Ultimate Matte Finish (< 5GU) Surface micro-creasing scatters light in all directions to achieve an ultra-low gloss level of 1° to 5°. This ensures exceptional color restoration—blacks look deeper and richer without the "milky" or "cloudy" appearance of traditional matte paints. |

|

|

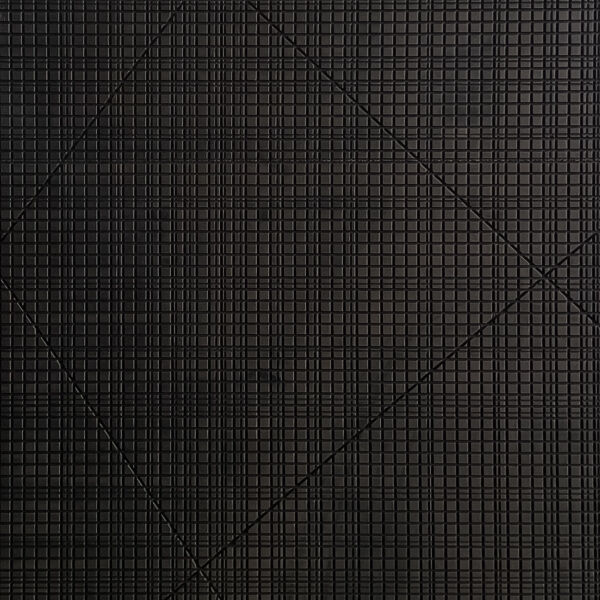

Silky "Skin-Feel" Touch The microscopic texture reduces the actual contact area between fingers and the surface, resulting in a warm, velvety sensation similar to infant skin or premium silk. |

|

|

Superior Anti-Fingerprint & Stain Resistance The combination of reduced contact area and a highly dense coating prevents finger oils from adhering to the surface. Any marks that do appear are easily wiped away. |

|

|

High Hardness & Scratch Resistance The 172nm high-density cross-linking process boosts surface hardness by 1–2 levels. This enhances scratch resistance and solves the common "polishing effect" (where scratches leave shiny marks) found in traditional soft-touch coatings. |

|