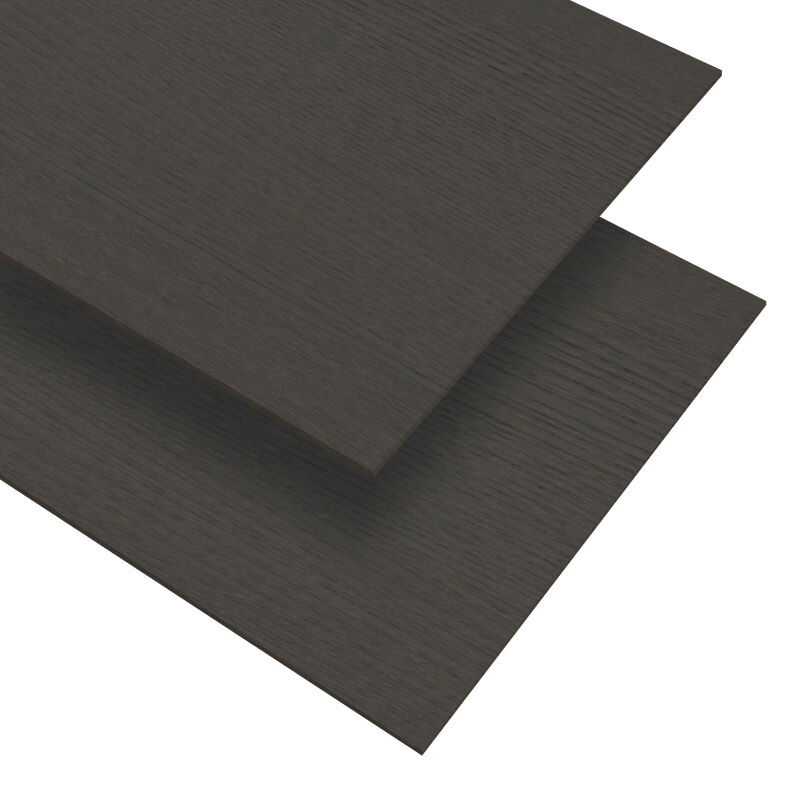

china wood veneer manufacturer

A China wood veneer manufacturer represents a sophisticated operation specializing in the production of high-quality wood veneers through advanced manufacturing processes. These facilities utilize state-of-the-art slicing and peeling equipment to transform raw timber into thin, decorative sheets that maintain the natural beauty of wood while offering practical application solutions. The manufacturing process involves careful log selection, precise cutting techniques, and quality control measures to ensure consistent product excellence. These facilities typically feature automated drying systems, computerized cutting equipment, and advanced sorting mechanisms that guarantee uniform thickness and quality across all products. The manufacturer's capabilities extend to producing various veneer types, including rotary-cut, plain-sliced, quarter-cut, and rift-cut veneers, catering to diverse customer requirements. Modern facilities also implement sustainable practices, optimizing raw material usage and minimizing waste through efficient production methods. They maintain strict moisture control systems and employ specialized storage facilities to preserve the veneers' quality before shipment. Additionally, these manufacturers often provide customization services, allowing clients to specify their preferred wood species, cut patterns, and dimensions.