hardwood panel for furniture making

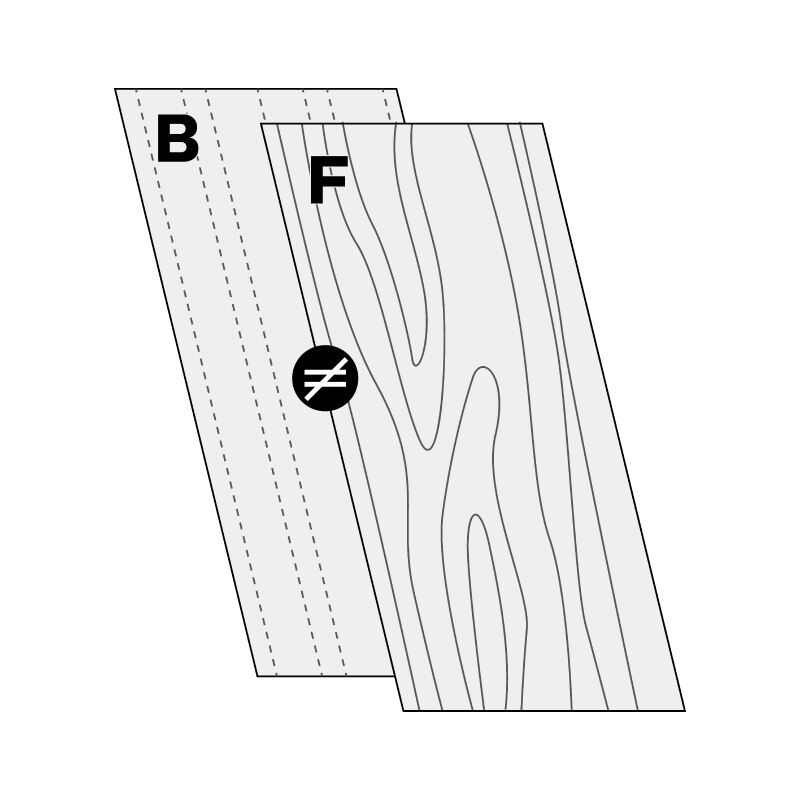

Hardwood panels for furniture making represent a cornerstone material in high-quality furniture manufacturing, offering exceptional durability and aesthetic appeal. These engineered wood products consist of carefully selected hardwood layers bonded together under high pressure and temperature, creating stable and robust panels ideal for various furniture applications. The manufacturing process involves precise selection of hardwood veneers, strategic layering for optimal strength, and advanced bonding techniques that ensure dimensional stability. These panels excel in both structural and decorative applications, providing furniture makers with versatile material that maintains its integrity across different environmental conditions. The panels feature cross-laminated construction, which significantly reduces wood movement and warping while enhancing the overall strength-to-weight ratio. Modern manufacturing techniques allow for consistent quality control, ensuring each panel meets strict industry standards for moisture content, density, and structural integrity. The panels can be finished with various hardwood veneers, offering countless design possibilities while maintaining the authentic look and feel of solid wood. Their application extends from cabinet making to high-end furniture production, interior doors, and decorative wall panels.