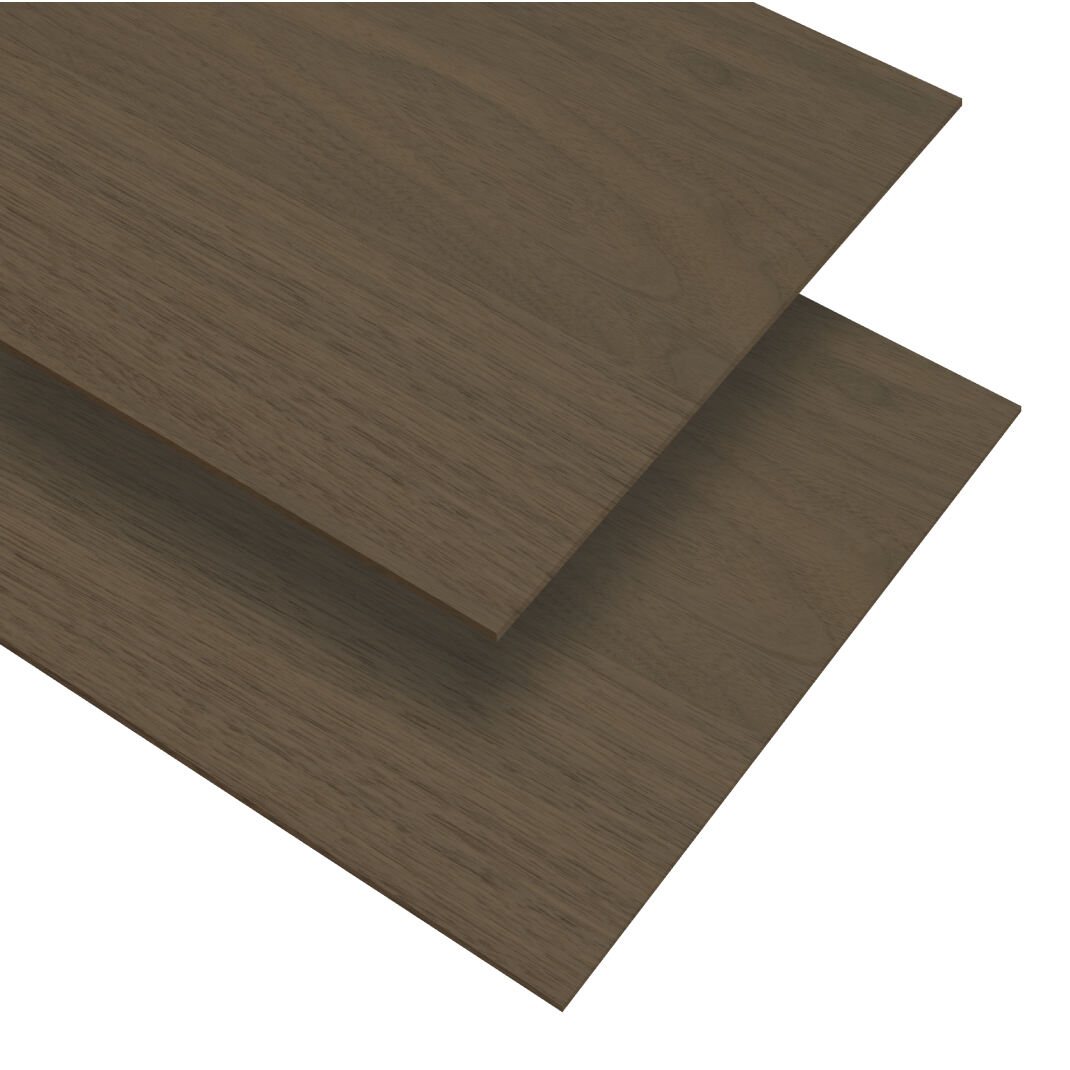

hardwood veneer panel

Hardwood veneer panels represent a sophisticated fusion of natural beauty and engineering excellence in modern woodworking. These panels consist of thin slices of premium hardwood bonded to a stable core material, typically plywood or MDF, creating a product that combines the aesthetic appeal of solid wood with enhanced structural stability. The manufacturing process involves carefully selecting and matching wood veneers, which are then precisely cut to ensure consistent thickness and quality. These panels offer exceptional versatility in both residential and commercial applications, from high-end furniture manufacturing to architectural installations. The core material provides dimensional stability while the veneer layer delivers the desired appearance of premium hardwood. Advanced adhesive technologies ensure a permanent bond between layers, resulting in a product that resists warping and splitting. Modern production techniques allow for various veneer patterns, including book-matched, slip-matched, and random-matched designs, providing designers and craftsmen with extensive creative possibilities. The panels are available in numerous wood species, from classic oak and maple to exotic varieties, each offering unique grain patterns and color variations.