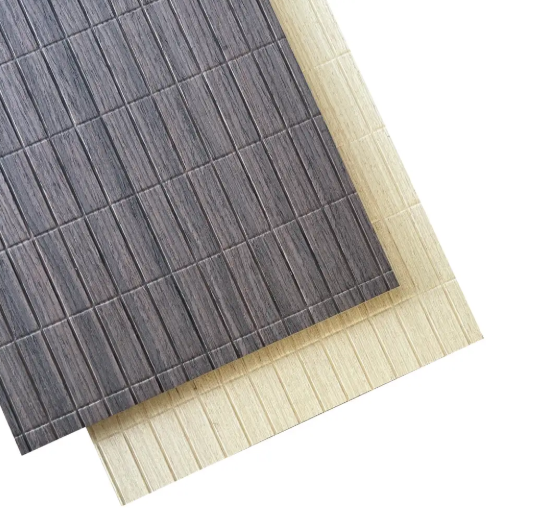

Door panels serve as essential components in both residential and commercial buildings, providing structural integrity, aesthetic appeal, and functional performance. However, like any building element, door panels are susceptible to various issues that can compromise their effectiveness and appearance. Understanding these common problems and their solutions can help property owners maintain their doors in optimal condition while extending their lifespan and preserving their investment.

Warping and Deformation Issues

Understanding Warping Mechanisms

Warping represents one of the most prevalent problems affecting door panels across various materials and environments. This deformation occurs when different sections of a door panel expand or contract at varying rates, typically due to moisture exposure, temperature fluctuations, or improper installation. Wooden door panels are particularly susceptible to warping because wood naturally absorbs and releases moisture based on environmental conditions. The cellular structure of wood causes it to swell when humidity increases and shrink during dry periods, creating internal stress that manifests as visible warping.

Environmental factors play crucial roles in door panel warping. Direct sunlight exposure can cause uneven heating, where one side of the panel heats more rapidly than the other, creating differential expansion. Similarly, proximity to heating systems, air conditioning units, or areas with significant temperature variations can accelerate warping processes. Poor ventilation around door installations can trap moisture, creating conditions conducive to panel deformation over time.

Prevention and Correction Strategies

Preventing door panel warping requires proactive measures during installation and ongoing maintenance. Proper sealing with high-quality primers and finishes creates barriers against moisture penetration, significantly reducing warping risks. Installation should include adequate clearances around the door panel to allow for natural expansion and contraction without binding against the frame. Regular maintenance schedules should include inspecting and refreshing protective coatings annually or as environmental conditions dictate.

When warping has already occurred, correction methods depend on the severity and type of deformation. Minor warping can often be addressed through careful application of moisture and controlled pressure over time. More severe cases may require professional intervention, including panel replacement or specialized straightening techniques. Climate control improvements in the surrounding environment can prevent future occurrences and protect new installations.

Surface Damage and Wear Patterns

Identifying Common Surface Problems

Surface damage on door panels manifests in various forms, each indicating different underlying causes and requiring specific treatment approaches. Scratches, dents, and impact marks are common in high-traffic areas where doors experience frequent use or contact with objects. These surface imperfections not only detract from aesthetic appeal but can also compromise the protective finish, allowing moisture and contaminants to penetrate the underlying material. Deep scratches that penetrate through protective coatings create entry points for moisture, potentially leading to more serious structural issues over time.

Chemical damage represents another category of surface problems, particularly in industrial or commercial environments. Cleaning products with harsh chemicals, accidental spills, or exposure to corrosive substances can cause discoloration, etching, or chemical burns on door panel surfaces. These types of damage often require specialized treatment and may necessitate refinishing or replacement depending on the extent of the damage.

Repair Techniques and Materials

Effective surface damage repair begins with thorough assessment and proper preparation. Minor scratches and scuffs can often be addressed through careful sanding with progressively finer grits, followed by appropriate refinishing techniques. The key lies in matching existing finishes and textures to maintain visual continuity across the entire door panel surface. Professional-grade wood fillers, putties, or specialized repair compounds can address deeper gouges or impact damage.

For more extensive surface damage, refinishing the entire panel may provide the most satisfactory results. This process involves complete removal of existing finishes, surface preparation, and application of new protective coatings. Modern refinishing materials offer enhanced durability and resistance to common causes of surface damage, providing long-term protection for restored door panels.

Hardware Integration Problems

Alignment and Mounting Issues

Hardware integration problems frequently affect door panel functionality and can create cascading issues if left unaddressed. Misaligned hinges represent a common problem that causes uneven stress distribution across the door panel, potentially leading to warping or cracking over time. When hinges are not properly aligned during installation or become misaligned due to settling or wear, the door panel bears uneven loads that can compromise its structural integrity. This misalignment often manifests as difficulty opening or closing, gaps around the door perimeter, or visible sagging.

Lock and handle mounting problems can also affect door panel performance. Oversized or improperly drilled holes for hardware installation can weaken the panel structure, while undersized holes can cause splitting or cracking when hardware is forced into place. The weight and stress concentration from heavy hardware assemblies require proper reinforcement and distribution techniques to prevent localized failure in the door panel material.

Hardware Maintenance and Upgrades

Regular hardware maintenance ensures optimal door panel performance and longevity. Lubrication of moving components prevents excessive wear and reduces stress on mounting points within the door panel. Periodic inspection of mounting screws and fasteners helps identify loosening before it leads to enlarged holes or structural damage. Tightening schedules should account for the specific materials involved and environmental factors that might accelerate loosening processes.

Upgrading hardware systems can address chronic problems while improving overall door panel functionality. Modern hardware designs often feature improved weight distribution, enhanced corrosion resistance, and better compatibility with various door panel materials. When upgrading, proper reinforcement of mounting areas may be necessary to accommodate new hardware configurations and ensure long-term reliability.

Moisture-Related Deterioration

Moisture Penetration Pathways

Moisture penetration represents a significant threat to door panel integrity, creating conditions for various forms of deterioration. Water can enter through compromised seals, damaged finishes, or construction joints around the door frame. Once moisture penetrates the door panel structure, it can cause swelling, delamination in composite materials, or rot in wooden components. Understanding moisture pathways helps property owners implement effective prevention strategies and identify early warning signs of moisture-related problems.

Environmental conditions significantly influence moisture penetration risks. Areas with high humidity, frequent precipitation, or poor drainage around building entrances create challenging conditions for door panel preservation. Additionally, temperature cycling can cause expansion and contraction that opens microscopic pathways for moisture entry, making even well-sealed panels vulnerable over time.

Moisture Protection and Remediation

Comprehensive moisture protection involves multiple layers of defense, beginning with proper installation techniques and high-quality sealing materials. Weather stripping, door sweeps, and frame seals create primary barriers against moisture intrusion. Regular inspection and maintenance of these protective elements ensures continued effectiveness and helps identify areas needing attention before moisture damage occurs.

When moisture damage has occurred, prompt remediation prevents further deterioration and potential health hazards from mold or mildew growth. Treatment approaches vary depending on the extent of moisture penetration and the specific door panel materials involved. Professional assessment may be necessary for severe cases to determine whether repair or replacement provides the most cost-effective solution.

Installation and Structural Concerns

Foundation and Frame Stability

Proper door panel installation requires adequate structural support from both the door frame and surrounding building elements. Settlement, structural movement, or inadequate framing can create stress concentrations that lead to door panel problems over time. When buildings settle or shift, door frames can become distorted, placing uneven loads on the door panel and causing operational difficulties or structural damage. Regular monitoring of frame alignment and building stability helps identify potential issues before they affect door panel performance.

Frame material selection and construction techniques significantly impact long-term door panel stability. Steel frames offer superior strength and dimensional stability but require proper corrosion protection. Wood frames provide good workability and aesthetics but need protection against moisture and insect damage. Composite frame materials combine advantages of different materials but require specific installation techniques and compatible fastening systems.

Professional Installation Standards

Professional installation standards ensure door panel longevity and optimal performance through attention to critical details often overlooked in amateur installations. Proper shimming and leveling during installation creates uniform support around the door panel perimeter, preventing stress concentrations that can lead to warping or cracking. Installation tolerances must account for seasonal movement while maintaining adequate sealing and operational clearances.

Quality control during installation includes verification of measurements, squareness, and proper hardware alignment before final fastening. Post-installation adjustments may be necessary to optimize performance and address any settling that occurs during initial service. Professional installers understand these nuances and can implement solutions that prevent common problems from developing over time.

Preventive Maintenance Strategies

Scheduled Inspection Programs

Implementing systematic inspection programs represents the most effective approach to preventing serious door panel problems. Regular visual inspections can identify early signs of warping, surface damage, or hardware issues before they require expensive repairs or replacement. Inspection schedules should account for environmental factors, usage patterns, and the specific materials involved in door panel construction. High-traffic installations or those exposed to harsh environmental conditions may require more frequent inspection intervals.

Documentation of inspection findings creates valuable maintenance records that help identify patterns and predict future maintenance needs. Digital photography can provide visual records of door panel condition over time, helping maintenance personnel track deterioration rates and make informed decisions about repair timing and methods. These records also prove valuable when evaluating warranty claims or planning building maintenance budgets.

Proactive Treatment Applications

Proactive treatment applications extend door panel life and prevent many common problems from developing. Regular cleaning with appropriate products removes contaminants that can cause chemical damage or provide conditions for biological growth. Protective coatings should be refreshed according to manufacturer recommendations and environmental exposure conditions, maintaining barriers against moisture, UV radiation, and mechanical damage.

Climate control improvements around door installations can significantly reduce stress on door panels and extend their service life. Proper ventilation prevents moisture accumulation, while temperature control reduces expansion and contraction cycles that contribute to warping and hardware loosening. Investment in environmental controls often pays dividends through reduced maintenance costs and extended door panel replacement intervals.

FAQ

How often should door panels be inspected for problems

Door panels should undergo visual inspection at least twice annually, typically in spring and fall, to assess their condition and identify emerging issues. High-traffic commercial installations or doors exposed to harsh environmental conditions may require quarterly inspections. During these inspections, look for signs of warping, surface damage, hardware loosening, or moisture penetration around seals and joints.

What causes door panels to warp and how can it be prevented

Door panel warping primarily results from uneven moisture exposure, temperature fluctuations, or improper installation. Prevention strategies include applying high-quality sealers and finishes, ensuring adequate ventilation around the installation, maintaining consistent indoor climate conditions, and using proper installation techniques with appropriate clearances for expansion and contraction.

Can damaged door panel surfaces be repaired or do they need replacement

Many surface damage issues can be successfully repaired through proper techniques and materials. Minor scratches and dents often respond well to sanding and refinishing, while deeper damage may require wood fillers or specialized repair compounds. The decision between repair and replacement depends on the extent of damage, cost considerations, and the overall condition of the door panel.

What environmental factors most commonly affect door panel longevity

Key environmental factors affecting door panel longevity include moisture levels, temperature variations, direct sunlight exposure, and air circulation patterns. High humidity or frequent wet conditions accelerate deterioration, while extreme temperature swings cause expansion and contraction stress. UV radiation from direct sunlight can degrade finishes and cause uneven heating that leads to warping.