Understanding the Timeless Beauty of Natural Wood Surfaces

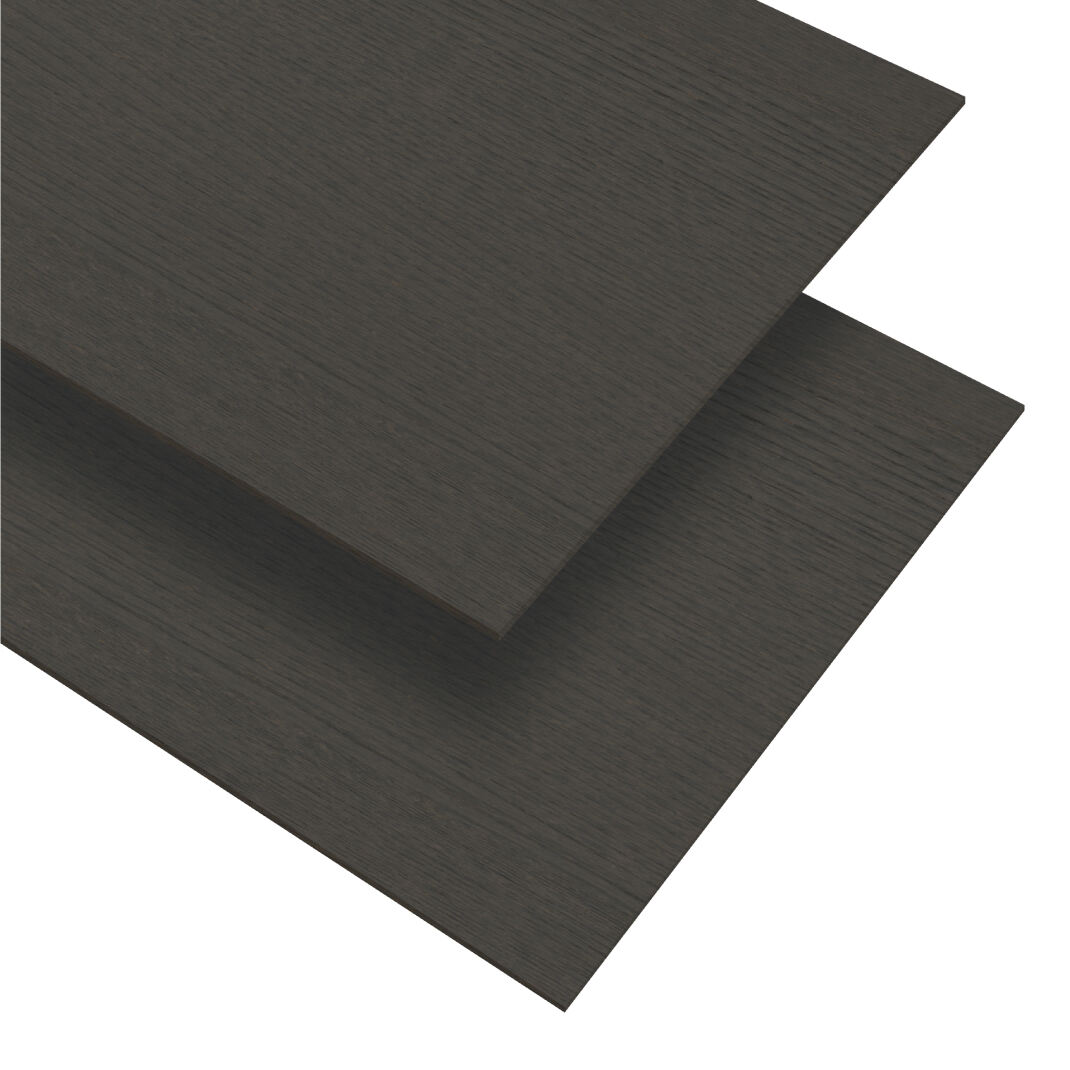

When it comes to creating stunning furniture and interior finishes, both wood veneer and solid wood offer distinct characteristics that can transform your space. The choice between these two materials often becomes a crucial decision point for homeowners, designers, and craftsmen alike. Each option brings its own set of advantages, applications, and aesthetic appeal to the table.

The debate between wood veneer and solid wood surfaces has evolved significantly over the years, with modern manufacturing techniques elevating the quality and durability of both options. Today's wood veneer products represent a remarkable fusion of artistry and technology, offering an increasingly sophisticated alternative to solid wood while maintaining the natural beauty of genuine timber.

The Nature and Creation of Wood Veneer

Manufacturing Process and Technology

Wood veneer creation is a precise and sophisticated process that begins with carefully selected logs. These logs are first softened through steaming or soaking, then mounted on specialized lathes or slicing machines. The equipment peels or slices the log into thin sheets, typically ranging from 0.2mm to 3mm in thickness. This methodical process ensures that each sheet of wood veneer maintains consistent thickness and quality.

Modern technology has revolutionized veneer production, introducing computer-controlled cutting systems that maximize yield and maintain exceptional quality control. These advanced methods allow manufacturers to create perfectly matched patterns and seamless surfaces that were impossible to achieve in the past.

Types and Varieties Available

The world of wood veneer offers an impressive array of options, from common species like oak and maple to exotic varieties such as bubinga and bird's eye maple. Natural wood veneer comes in different cuts - rotary, quarter, rift, and flat cut - each producing distinct grain patterns and visual effects. Contemporary manufacturing also offers reconstituted veneers, where dyed wood layers are reassembled to create consistent, repeatable patterns.

Designers and manufacturers can choose from hundreds of species and cuts, allowing for incredible creative flexibility. This variety enables the creation of unique patterns and designs that might be impossible or prohibitively expensive with solid wood.

Advantages of Choosing Wood Veneer

Environmental Benefits

One of the most compelling arguments for wood veneer is its environmental impact. From a single log, manufacturers can produce enough wood veneer to cover approximately twenty times more surface area compared to solid wood boards. This efficiency significantly reduces the demand for timber resources, making wood veneer a more sustainable choice for large-scale projects.

The production process also generates less waste compared to solid wood manufacturing, as modern veneer cutting techniques utilize computer optimization to maximize yield from each log. This resource efficiency extends to transportation costs and carbon footprint, as veneer sheets are lighter and more compact to ship than solid wood.

Cost-Effectiveness and Accessibility

Wood veneer provides an economical solution for achieving high-end wood aesthetics without the premium price tag of solid wood. This cost advantage becomes particularly significant in large-scale projects or when working with rare wood species. The material allows designers and homeowners to incorporate luxurious wood appearances into their projects while maintaining budget control.

The accessibility of wood veneer also means that exotic and rare wood species become more attainable for a broader range of projects. Species that might be prohibitively expensive or even unavailable in solid form can be readily accessed through veneer options.

Solid Wood Characteristics and Benefits

Durability and Longevity

Solid wood has earned its reputation for exceptional durability over centuries of use in furniture and construction. Its thick, uniform composition allows for multiple refinishing cycles, potentially extending the life of the piece for generations. The material's natural strength and resistance to wear make it particularly suitable for high-traffic areas and frequently used furniture pieces.

The ability to sand and refinish solid wood multiple times provides a significant advantage in terms of maintenance and restoration. This characteristic allows solid wood pieces to maintain their beauty and functionality through decades of use, often increasing in value as they age.

Authenticity and Value

The inherent value of solid wood stems from its complete authenticity and unique character. Each piece tells its own story through grain patterns, knots, and natural variations that develop over time. This authenticity creates an emotional connection that many people seek in their furniture and interior elements.

Solid wood's natural aging process often enhances its appearance, developing a rich patina that adds character and depth to the material. This natural evolution of the wood's appearance contributes to its enduring appeal and potential investment value.

Making the Right Choice for Your Project

Application Considerations

The decision between wood veneer and solid wood often depends on the specific requirements of your project. Wood veneer excels in applications requiring large, flat surfaces, such as cabinet doors, wall panels, and commercial furniture. Its stability in these applications often surpasses that of solid wood, which can be prone to warping or movement in large panels.

Solid wood, however, remains the preferred choice for structural elements, exposed edges, and pieces that require substantial carving or shaping. The material's thickness and strength make it ideal for table legs, chair frames, and architectural millwork where structural integrity is paramount.

Maintenance Requirements

Both materials require proper care to maintain their beauty and longevity, but their maintenance needs differ. Wood veneer surfaces typically require gentle cleaning and protection from excessive moisture or direct sunlight. Regular dusting and the use of appropriate wood cleaners help preserve the veneer's appearance.

Solid wood maintenance might involve more intensive care, including periodic refinishing and careful attention to environmental conditions to prevent warping or cracking. However, this maintenance investment is offset by the material's ability to be fully restored through sanding and refinishing.

Frequently Asked Questions

Can wood veneer be repaired if damaged?

Yes, wood veneer can be repaired, though the process requires skill and proper techniques. Small damages can be fixed using wood fillers or patches, while more severe damage might require replacing the affected veneer section. Professional restoration specialists can often achieve seamless repairs that maintain the original appearance.

How long does wood veneer typically last?

With proper care and maintenance, wood veneer can last for decades. Modern manufacturing techniques and improved adhesives have significantly enhanced the durability of wood veneer products. The lifespan largely depends on environmental conditions, usage patterns, and maintenance practices.

Is wood veneer real wood?

Yes, wood veneer is made from real wood, specifically thin slices cut from actual timber. While some synthetic alternatives exist in the market, authentic wood veneer consists of natural wood layers typically ranging from 0.2mm to 3mm in thickness, preserving the genuine characteristics and beauty of the original wood species.