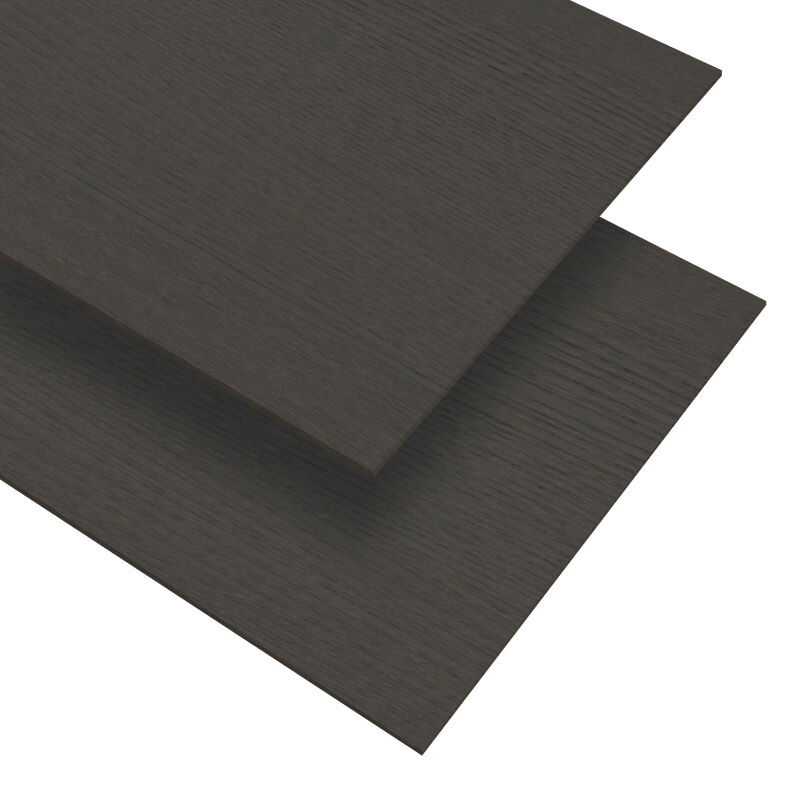

custom hardwood panel

Custom hardwood panels represent a pinnacle of modern woodworking technology, combining traditional craftsmanship with innovative manufacturing processes. These versatile architectural elements are engineered to precise specifications, featuring carefully selected hardwood veneers bonded to high-quality core materials. Each panel is meticulously crafted to meet specific dimensional requirements, moisture resistance standards, and aesthetic preferences. The panels utilize advanced adhesive systems and precise machining techniques to ensure exceptional stability and durability across varying environmental conditions. They serve multiple applications in both residential and commercial settings, from wall cladding and ceiling installations to high-end furniture manufacturing and architectural millwork. The manufacturing process incorporates sophisticated moisture control systems and precise temperature regulation to maintain optimal material consistency. These panels can be customized with various surface treatments, including fire-retardant coatings, UV protection, and specialized finishes to enhance their performance characteristics. The versatility of custom hardwood panels extends to their ability to accommodate different installation methods, including tongue and groove systems, clip mounting, and traditional fastening techniques.