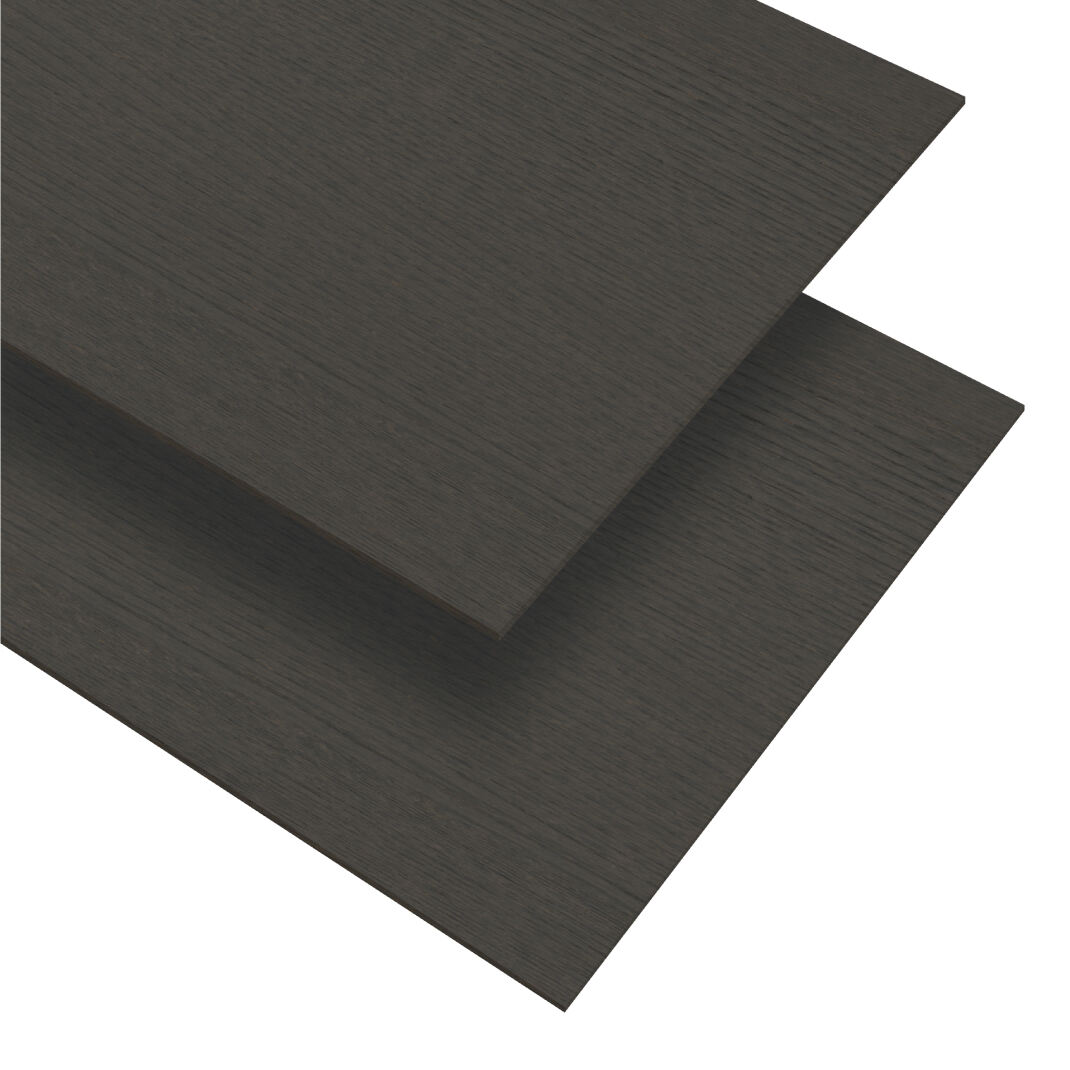

rotary cut wood veneer

Rotary cut wood veneer represents a sophisticated method of wood processing that transforms logs into thin, continuous sheets of wood through a specialized cutting process. In this technique, debarked logs are first softened through steaming or hot water treatment, then mounted on a lathe that rotates against a fixed blade, peeling off layers of wood in a continuous motion, much like unrolling a roll of paper. This process creates consistent, wide sheets of veneer that showcase the wood's natural grain patterns. The thickness of these veneers typically ranges from 0.2mm to 3mm, making them ideal for various applications. The technology behind rotary cut veneer production has evolved significantly, now incorporating computerized controls for precise thickness management and optimal yield. These veneers are extensively used in the manufacture of plywood, engineered wood products, and decorative surfaces for furniture, cabinetry, and architectural applications. The process is particularly efficient for processing larger diameter logs and is known for its high yield and cost-effectiveness compared to other veneer cutting methods.