When selecting materials for furniture making, cabinetry, or architectural millwork, the quality of your foundational components determines the success of your entire project. Milled panels represent one of the most versatile and reliable options available to craftspeople, builders, and designers seeking precision-engineered wood products. These carefully manufactured panels offer superior dimensional stability, consistent grain patterns, and predictable performance characteristics that traditional solid lumber often cannot match. Understanding the nuances of panel selection, from species characteristics to manufacturing processes, empowers you to make informed decisions that enhance both the aesthetic appeal and structural integrity of your finished work.

Understanding Panel Construction Methods

Traditional Solid Wood Panel Assembly

Traditional solid wood panels maintain the authentic characteristics of natural lumber while providing enhanced stability through careful joinery techniques. Master craftspeople select individual boards based on grain compatibility, moisture content uniformity, and structural soundness before edge-gluing them into larger panels. This method preserves the natural beauty of wood grain flow while creating surfaces suitable for demanding applications. The edge-gluing process requires precise milling to ensure tight, invisible seams that maintain structural integrity throughout seasonal wood movement cycles.

Quality solid wood panels undergo extensive preparation including kiln-drying to optimal moisture levels, typically between six and eight percent for interior applications. Surface preparation involves multiple passes through industrial planers to achieve uniform thickness tolerances within thousandths of an inch. This precision ensures consistent results when multiple panels are joined together in larger assemblies or when panels interface with other millwork components.

Engineered Panel Technologies

Modern engineered panel construction combines natural wood fibers with advanced adhesive systems to create products that often surpass solid wood in specific performance characteristics. Medium-density fiberboard panels offer exceptional surface smoothness and dimensional stability, making them ideal substrates for painted finishes or veneer applications. Particleboard variants provide cost-effective solutions for applications where strength-to-weight ratios favor engineered construction over traditional solid wood methods.

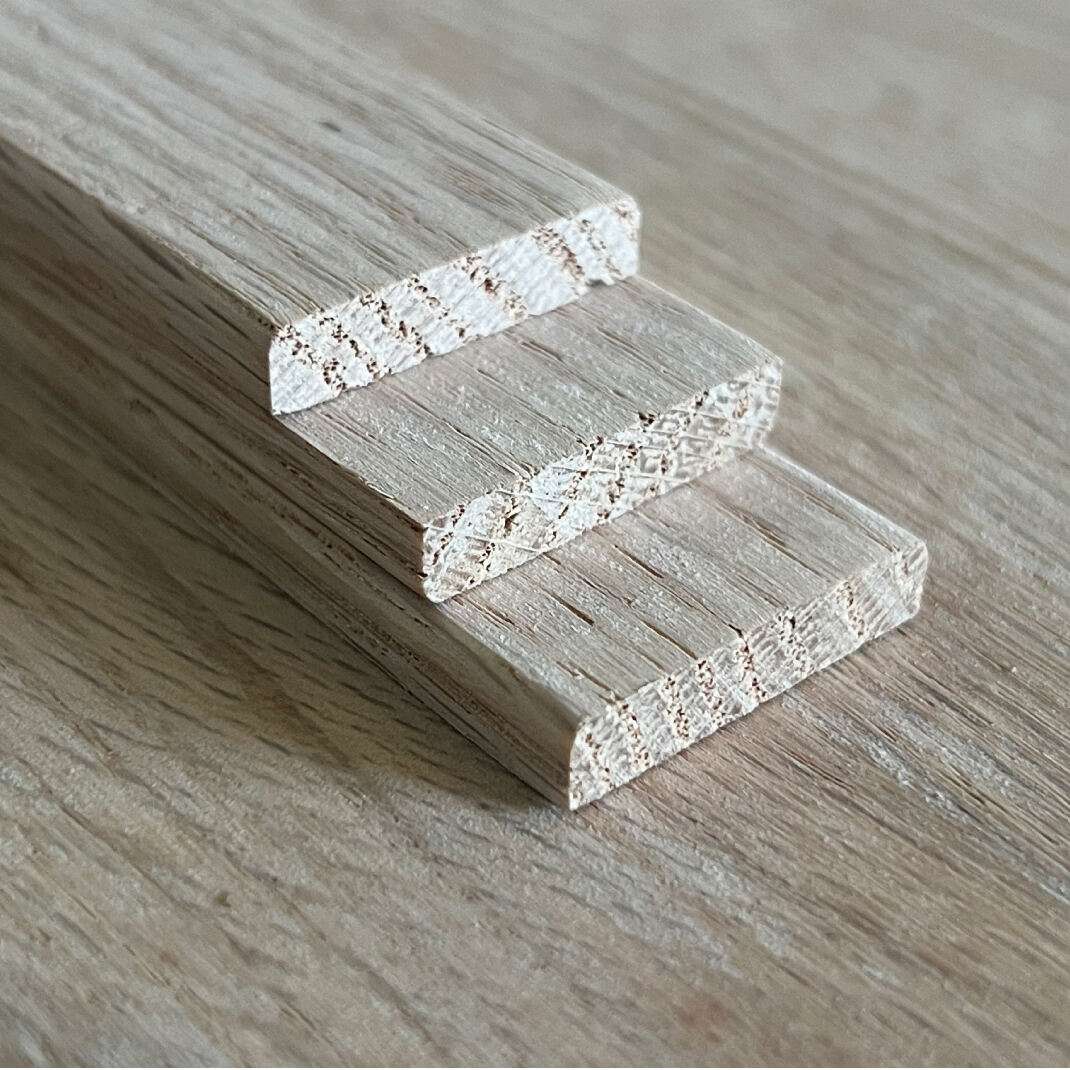

Plywood construction utilizes cross-laminated veneer layers to create panels with superior strength properties in multiple directions. This construction method minimizes the seasonal movement that affects solid wood while maintaining many desirable characteristics of natural lumber. Advanced manufacturing processes ensure consistent core density and moisture distribution, resulting in panels that machine cleanly and accept fasteners reliably throughout their service life.

Species Selection Considerations

Hardwood Panel Characteristics

Hardwood species selection significantly impacts both the aesthetic qualities and performance characteristics of finished milled panels. Dense hardwoods like maple and cherry provide exceptional durability and accept fine detail work, making them preferred choices for furniture faces and decorative millwork. These species typically exhibit tight, consistent grain patterns that enhance the visual appeal of larger panel surfaces while maintaining structural stability under varying environmental conditions.

Walnut and mahogany offer rich color variations and distinctive grain characteristics that create striking visual effects in panel applications. These premium species often justify their higher costs through superior workability, finishing characteristics, and long-term durability. When properly processed into milled panels, these hardwoods develop natural patinas that enhance their beauty over time while maintaining dimensional stability through proper construction techniques.

Softwood Panel Applications

Softwood panels excel in structural applications where strength-to-weight ratios and cost considerations outweigh aesthetic concerns. Pine, fir, and cedar varieties provide reliable performance in construction applications while offering natural resistance to moisture and insect damage. These species typically accept stains and finishes readily, allowing them to complement hardwood components in mixed-material projects.

Cedar panels bring natural aromatic properties that provide pest deterrence while contributing distinctive visual characteristics to specialty applications. The lightweight nature of most softwood panels simplifies handling during installation while maintaining adequate strength for most residential and light commercial applications. Proper grade selection ensures that softwood panels meet specific performance requirements without unnecessary material costs.

Manufacturing Quality Indicators

Precision Milling Standards

Professional-grade manufacturing facilities maintain strict tolerances that ensure consistent panel dimensions and surface quality across production runs. Thickness variations should not exceed plus or minus 0.005 inches across panel surfaces, with edge straightness maintained within similar tolerances. These precision standards enable seamless integration with other millwork components while minimizing fitting adjustments during installation.

Surface finish quality reflects the caliber of manufacturing equipment and operator expertise. Premium milled panels exhibit smooth, tear-out-free surfaces that require minimal sanding before finish application. Consistent grain orientation and matched color tones across panel faces indicate careful material selection and processing protocols that distinguish professional-grade products from commodity alternatives.

Adhesive System Reliability

Modern panel manufacturing employs sophisticated adhesive formulations designed to withstand specific environmental conditions and stress patterns. Structural adhesives used in milled panels must demonstrate bond strength that equals or exceeds the wood fiber strength of the substrate materials. This ensures that panel failure occurs through wood fracture rather than adhesive failure, maintaining structural integrity throughout the panel's service life.

Quality manufacturers subject their adhesive systems to accelerated aging tests that simulate decades of environmental exposure in compressed timeframes. These testing protocols validate long-term performance characteristics while identifying potential failure modes before products reach market. Documentation of these test results provides confidence in panel performance under demanding application conditions.

Application-Specific Selection Criteria

Interior Millwork Requirements

Interior millwork applications demand panels that maintain dimensional stability under controlled environmental conditions while providing superior surface quality for finish applications. Moisture content specifications typically range from six to nine percent, with tighter tolerances required for precision fitting applications. Panel thickness uniformity becomes critical when multiple pieces must align perfectly in complex assemblies or when panels interface with machined hardware components.

Color matching requirements for interior applications often necessitate panels sourced from carefully managed lumber lots that exhibit consistent grain patterns and natural coloration. This attention to aesthetic consistency distinguishes high-end millwork from utilitarian applications where function takes precedence over visual appeal. Premium interior panels often undergo additional selection processes to eliminate natural defects that might compromise appearance quality.

Structural Application Demands

Structural applications require panels that meet specific load-bearing requirements while maintaining dimensional stability under varying environmental conditions. Engineering specifications typically include minimum density requirements, moisture resistance standards, and fastener-holding capacity ratings that ensure adequate performance margins for intended applications. These technical requirements often necessitate engineered panel construction methods that optimize strength characteristics.

Environmental exposure considerations influence species selection and manufacturing processes for structural panel applications. Panels intended for high-moisture environments require enhanced adhesive systems and may benefit from pressure-treatment processes that improve long-term durability. Load distribution characteristics and deflection limits under specified loads become primary selection criteria that may override aesthetic considerations in structural applications.

Quality Assessment Techniques

Visual Inspection Methods

Comprehensive visual inspection reveals critical information about panel quality and manufacturing consistency. Surface examination should identify any tear-out, chipping, or burn marks that indicate suboptimal machining parameters during manufacturing. Edge quality assessment includes checking for consistent thickness, square corners, and clean, chip-free cuts that facilitate precise joinery operations.

Grain pattern evaluation helps identify panels with optimal aesthetic characteristics while revealing potential structural weaknesses. Consistent grain orientation across panel faces indicates careful material selection and processing, while dramatic grain variations may signal the use of mismatched lumber sources. Color uniformity assessment helps ensure that finished projects maintain consistent appearance characteristics across all panel components.

Performance Testing Protocols

Systematic performance testing validates panel characteristics that affect long-term success in specific applications. Moisture content measurement using calibrated electronic meters ensures that panels meet specifications for intended environmental conditions. Flatness measurement using precision straightedges or laser measurement systems identifies panels that may cause fitting problems during installation.

Density measurement provides insights into material consistency and structural characteristics that affect both workability and performance. Variations in density across panel surfaces can indicate manufacturing inconsistencies that may cause problems during machining or finishing operations. Comprehensive testing protocols help identify superior panels while avoiding potential problem materials before they compromise project outcomes.

Installation and Handling Best Practices

Proper Storage Techniques

Proper storage maintains panel quality between delivery and installation while preventing damage that could compromise project success. Flat storage on level surfaces prevents warping and stress concentration that might develop during extended storage periods. Adequate air circulation around stored panels helps maintain uniform moisture content while preventing the development of surface mold or staining that could affect finish quality.

Protection from moisture exposure remains critical throughout the storage period, as even brief exposure to high humidity can cause dimensional changes that affect fitting accuracy. Covering materials should allow air circulation while preventing direct moisture contact. Temperature stability helps maintain consistent panel dimensions and prevents stress development that might cause cracking or splitting during subsequent machining operations.

Machining Considerations

Successful machining of milled panels requires understanding of their construction characteristics and appropriate tool selection for specific panel types. Sharp cutting tools minimize tear-out while producing clean edges that accept glue and finishes effectively. Feed rates and cutting speeds must be optimized for specific panel densities and adhesive systems to prevent burning or chip-out that compromises edge quality.

Grain direction awareness becomes particularly important when machining solid wood panels, as cutting against grain direction can cause significant tear-out that requires extensive repair work. Proper work-holding techniques prevent panel movement during machining operations while avoiding clamping damage that might show in finished surfaces. Sequential machining operations should be planned to maintain reference surfaces throughout the fabrication process.

FAQ

What thickness options are available for milled panels

Milled panels are commonly available in standard thicknesses ranging from half-inch to two inches, with three-quarter inch being the most popular for furniture and cabinet applications. Custom thickness options can often be specified for special applications, though minimum order quantities may apply. Thickness selection should consider both structural requirements and compatibility with existing millwork components in your project.

How do environmental conditions affect panel performance

Environmental conditions significantly impact panel dimensional stability, with humidity changes causing the most noticeable effects. Panels acclimated to installation environments for at least 48 hours before use will exhibit minimal movement after installation. Engineered panels typically show less environmental sensitivity than solid wood panels, making them preferable for applications with variable humidity conditions.

What quality differences exist between panel manufacturers

Panel quality varies significantly between manufacturers based on material selection standards, manufacturing precision, and quality control processes. Premium manufacturers typically maintain tighter dimensional tolerances, use superior adhesive systems, and implement more rigorous material grading standards. These quality differences often justify price premiums through improved workability, appearance consistency, and long-term performance reliability.

How should panels be prepared for finishing

Panel preparation for finishing typically involves progressive sanding through increasingly fine grits, starting with 120-grit and progressing to 220-grit for most applications. Surface cleaning with compressed air or tack cloths removes sanding debris that could interfere with finish adhesion. Some panel types may require sealer application before final finishing to ensure uniform color and sheen development across the entire surface.